A German start-up offers a new, fully automated way of injection moulding frames from reinforced carbon-composites – in Europe. This process promises to cut the production time of fully recyclable bicycle frames to less than two minutes.

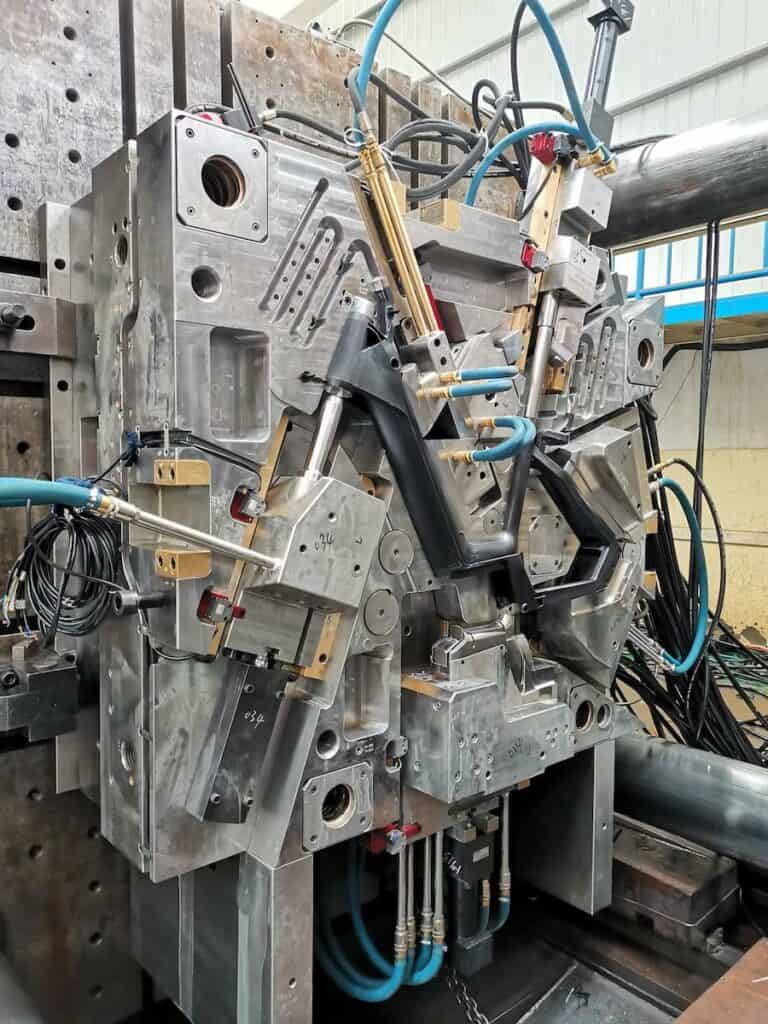

If the Eurobike trade show had gone ahead last year, V Frames would have been a highlight: the Thuringia-based spin-off of German composites specialist Isoco announced a new way to produce bicycle frames, taking a specific aim at e-bike frames built around mid-motors. Using the far-reaching experience of its parent company, V Frames (formerly known and originally launched as Velosione) claims it can produce an entire frame in about 90 seconds, using advanced injection moulding technologies.

Making this offer even more appealing to the bicycle industry is V Frames’ claim that their frames are fully recyclable, answering one of the industry’s current headaches caused by the trend towards carbon frames that currently end up in landfills. Also, V Frames says its way of producing frames cuts carbon dioxide emissions in half. Since the production process eliminates most of the human labor, it addresses one of the biggest hurdles for reshoring of the production of bicycle frames, namely high labor costs. It also promises a high degree of consistency in terms of build quality.

The drawback of this frame building method are high tooling costs, so the most obvious customers for V Frames would be sharing operators who need large fleets of identical bicycles. As the upcoming Norwegian e-bike brand Buddybike shows, V Frames’ way of building bicycle frames can be put to good use by smaller brands as well. With the help of Eker Design, Buddybike has achieved this with its upcoming SX1 model by using a unisex, mixté-like frame that can be fitted to a large range of rider sizes and even to different brands of mid-motors, using a series of adapter solutions.

Probably the most amazing part about the cooperation of V Frames and Buddybike is the time line: From first contacting V Frames in February 2021 to rolling out the first finished and rideable prototypes, it only took a few months. According to Buddybike, the SX1 model should become commercially available by 2022, i.e. within just nine months of starting the cooperation. As of Q2 of 2022, the SX1 frame will be available for other bicycle manufacturers as well. Given the current bottlenecks affecting frame manufacturing, this efficiency should turn some heads within the industry and get some product managers thinking whether V Frames thermo-injected bicycle frames are an option worth considering.